Portable drum rollers are available drum with 20 RPM fixed speed, or variable speed to rotate a 55-gallon (210 liter) drum from 15 to 24 RPM

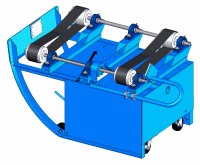

210L Portable Drum Rotator:

- Compact industrial drum mixer rolls a closed drum on its side to agitate the contents.

- Mixing contents inside a sealed drum eliminates worker exposure and reduces clean-up.

- Use separate drum for each batch.

- Portable drum mixers agitate drum contents without opening the drum!

- Utilise important ingredients that would otherwise be left in unmixed sediment.

- Eliminate the clean-up of insertion mixers.

- Use as a drain stand to dispense into a 5-gallon (20 liter) pail.

Agitate your drum’s contents without even opening the drum! Incorporate important stratified or settled ingredients and eliminate sediment in the bottom of your drum.

Mixing in closed drums eliminates the hazards of worker exposure, and the messy cleanup associated with insertion mixers. This compact, portable mixer rolls a closed drum to blend the contents. You may also dispense directly from a drum through a faucet.

The built-in tipping bar provides leverage to assist in loading a drum upright onto the drum roller, and setting the drum back to upright when drum mixing is finished. The sides and back are enclosed to protect the drive.

Wheeled Portable Drum Rollers to rotate a steel drum on its side. Add Option # POLY-201 to roll a plastic drum

Wheeled Portable Drum Rollers to rotate a steel drum on its side. Add Option # POLY-201 to roll a plastic drum

Pour directly into a 5-gallon pail

Pour directly into a 5-gallon pailfrom Portable Drum Mixer. Faucet can be attached to drum while rotating.

Improved Top Rim Hook to help pull the drum over to rolling position

Improved Top Rim Hook to help pull the drum over to rolling position

Enclosure with Safety Interlock (Sold Separately) to meet OSHA requirements, shown with Portable Drum Roller

Enclosure with Safety Interlock (Sold Separately) to meet OSHA requirements, shown with Portable Drum Roller

OSHA Requires Enclosure with Safety Interlock for ALL drum rotators

Features of Morse Portable Drum Rollers:

- Compact industrial drum roller only 21″ wide by 35″ long (53 x 89 cm)

- Tipping lever with hook engages drum top rim to load drum onto the drum roller

- Roll various sized drums… Options to roll plastic drum or 5-gallon pail

- Use as drain stand to dispense from drum

- Enclosed sides and back protect the drive mechanism

- Drum mixers available with various motors

– Single or 3 phase electric motors

– Explosion-proof electric

– 50Hz or 60Hz electric motors

– Air powered (Air Motor Technical Information)

Capacity of Portable Drum Rollers

- Liquid Load: 500 Lb. (227 kg)

- Dry Load varies with drum RPM as a shifting dry load exerts greater stress on the drum mixer.

350 Lb. (159 kg) at 15 RPM

300 Lb. (136 kg) at 20 RPM

250 Lb. (113 kg) at 24 RPM - Roll a drum on 4 drive and 4 idler oil-resistant, neoprene, 4″ (10.16 cm) diameter wheels

- Roll a drum with:

6″ to 28″ (15 to 71 cm) in diameter

Up to 40″ (101.6cm) tall. Note: The tipping lever will only engage a drum 30″ (76.2 cm) or taller.

Allow you to vary drum rotation speed from 15 to 24 RPM (13 to 20 RPM on 50Hz models).

RPM is based on a 22.5″ (57.2 cm) diameter drum.

– Ideal for experimental use

– Allows fast initial drum rolling, then reduce speed for continued, gentle agitation

Fixed Speed Portable Drum Rollers

Roll a 22.5″ (57 cm) diameter drum at 20 RPM (16 RPM on 50Hz models).

The RPM of these model cannot be changed.

Customers use Morse Drum Mixers to:

- Blend batches of powder

- Ensure uniform batches

- Mix paint, oils, urethane resin, plastisol, glue, dyes, flavors, etc.

- Mix chemicals into homogenous product prior to use

- Keep epoxy from separating

- Grind and smooth parts in media

- Homogenize tailings and sediment samples

- Plasma spray powder mixing

- . . .and my favorite, “Roll propellant casting tubes for chemical prep prior to cast”

The new kick stand design is easier to deploy and better supports the drum roller in upright position

The new kick stand design is easier to deploy and better supports the drum roller in upright position

Place your drum onto the base plate of the drum mixer with a drum truck or a below-hook drum lifter.

Place your drum onto the base plate of the drum mixer with a drum truck or a below-hook drum lifter.

Engage the chine hook onto the

Engage the chine hook onto thetop rim of the drum, and use the built-in retractable tipping lever to load a heavy drum from upright, to rolling position on the drum mixer

Combine Two Components to Meet Safety Requirements

Guard Enclosure with Safety Interlock, so that drum rotator automatically shuts of if enclosure gate in opened.

Install all Morse Rotators in accordance with requirements for enclosure and safety interlock, etc. One way to accomplish this is with a Morse enclosure with safety interlock, so the rotator automatically turns off when enclosure door is opened. Power connections and motor controls must also comply with applicable local codes.

For OSHA compliance in the USA, see OSHA subpart O.1910.212(a)(4) “Barrels, containers, and drums. Revolving drums, barrels, and containers shall be guarded by an enclosure which is interlocked with the drive mechanism, so that the barrel, drum, or container cannot revolve unless the guard enclosure is in place.”

Drum Mixer OPTIONS:

Add Option # 1-5P Idler Attachment to Roll a 5 Gallon (20 liter) Can

- Extends usefulness of the drum mixer to roll a 1 to 5 gallon cylindrical can up to 18″ (45.7 cm) tall

- Adjustable spacers for various heights of pail or can up to 17″ (43 cm) tall

- Bolt onto portable drum roller with 4 bolts

- This option is for 201 and 201VS portable drum rollers. It CANNOT be used for belted drum rollers.

Also see 5-Gallon Can Tumblers designed specifically to tumble 1 to 5 gallon cans / pails end over end to more vigorously mix the contents

Add Option # POLY-201 to Roll a Plastic Drum on the same drum mixer

Option # POLY-201 is factory installed on a new Portable Drum Roller It includes the following:

- Two extra wheels on each side support plastic drum. The weight is then distributed over a total of 12 wheels.

- End stop to prevent a plastic drum from traveling lengthways while being rolled.

- Chain to latch around the top of the drum while tipping from upright to horizontal rolling position on the drum mixer. The chain should then be released during drum rolling.

- Units with this option installed ship on a skid and add 62 Lb. (28 kg) to the ship weight.

NOTE: You can roll a plastic OR a steel drum with Option # POLY-201 installed

Kit # POLY-201FI is for Field Installation on your existing portable drum roller. With this kit installed, you can roll a plastic or steel drum.

Poly Roll Plastic Drum Kit (PDF)

Belted Portable Drum Rollers for a Fiber Drum

Belted portable drum rollers are available with the same drum speeds and motor types.

Capacity of Belted Portable Drum Rollers

- Liquid Load: 300 Lb. (136 kg)

- Dry Load varies with drum RPM. A shifting dry load exerts greater stress on the drum mixer.

300 Lb. (136 kg) at 10 to 20 RPM

250 Lb. (113 kg) at 24 RPM - Roll a drum on 2 belts

- Roll a fiber drum:

From 16″ to 23″ (41 to 59 cm) in diameter

Up to 35″ (89 cm) tall, and at least 30″ (76.2 cm) tall.

Belted portable drum rollers are designed to roll a Fiber Drum

- 16″ to 23″ (41 to 59 cm) in diameter

- Up to 35″ (89 cm) tall

- Minimum of 30″ (76.2 cm) tall

Custom Stainless Steel Drum Roller

Portable Drum Rotators with standard 1/2 HP, 60Hz, 1 phase TEFC motor include switch, cord and plug. All other electric 55-gallon (210 liter) drum mixers (i.e. Explosion proof, air powered, 3 phase, etc.) are shipped without switch, cord and plug. These must be installed by electrician according to local codes and customer’s preference.

Explosion Proof motors are rated for Class I Group D, and Class II Groups F and G.

* Expect a 20% reduction in drum RPM for models with 50 Hz motors.

Air motors are vane-type and require correctly sized filter, regulator, lubricator, valve (FRL) and piping supplied by customer.

Filter, regulator and lubricator (FRL) may be ordered from Morse as Part # 90020-P. Description: KIT, 3/8″ FRL & BALL VALVE